EFFICIENCY

Energy Efficiency

%30-50 ELECTRICITY SAVINGS

After dyeing, knitted and woven fabrics are washed with up to four times less water and in up to four times less time compared to standard dyeing tanks. It does not cause creases, whiteness, or pilling on the fabric surface. It is the most efficient rope washing machine in its field, designed to wash with the least amount of water.

%30-50 ELECTRICITY SAVINGS

HIGHER FASTNESS

%40-50 CAPACITY INCREASE

%50-80 WATER SAVINGS

%50-80 STEAM SAVING

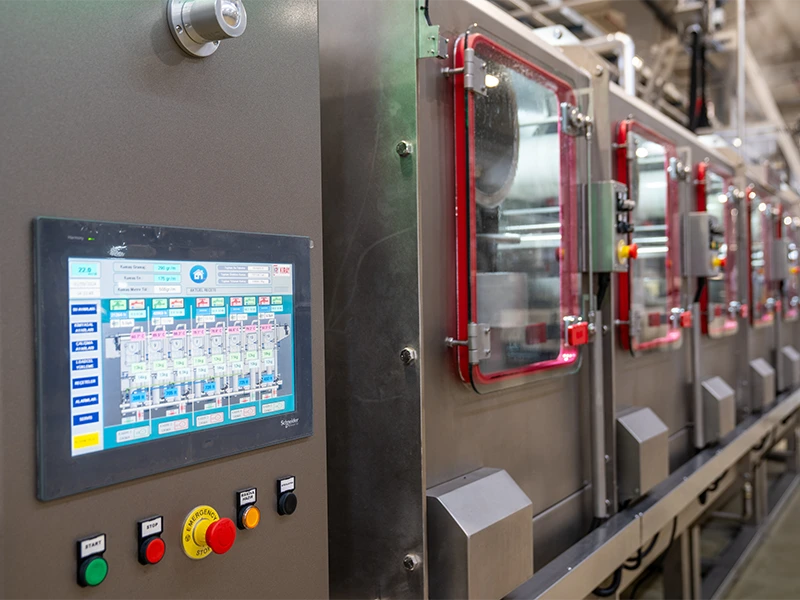

It is an operator-friendly washing machine, designed for ease of use. The heating system is equipped with a heat exchanger, allowing a maximum heating temperature of 98°C. Additionally, the adjustable overflow level feature with the pumped overflow function ensures maximum washing efficiency with minimal water consumption. It provides flexibility for different fabric types.

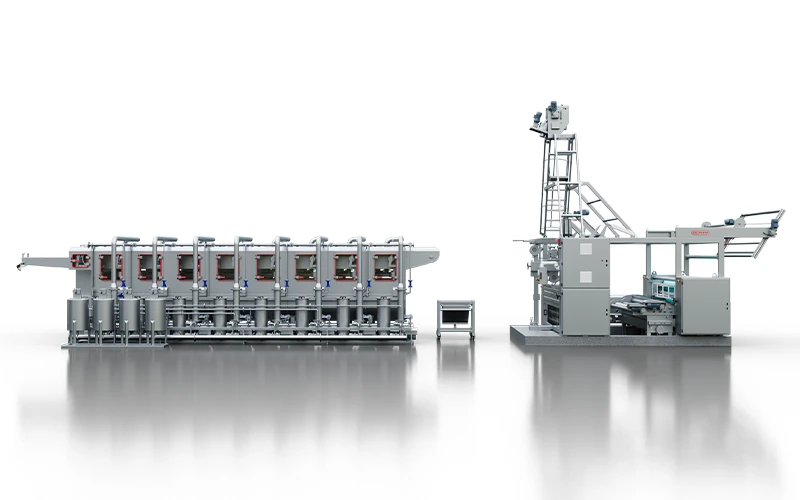

The KIRAY HYM-1923 D Rope Washing Machine consists of 5 baths, 16 J-boxes, and 32 washing nozzles.

Effective and gentle washing with a 140 mm nozzle diameter.

It consists of combinations containing 2 and 4 j-boxes.

5-50 kg fabric capacity

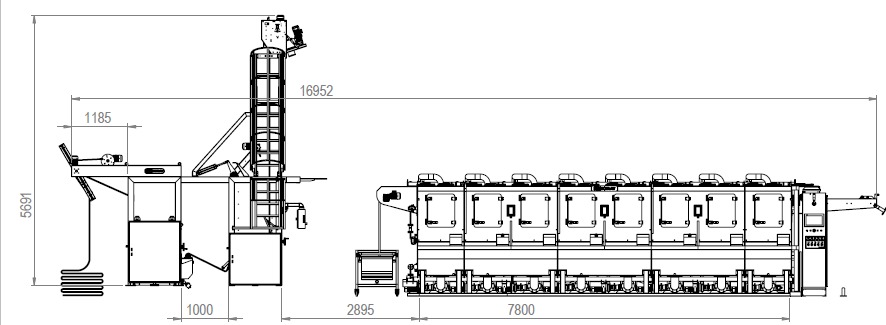

| Machine Dimesions | 3800 x 16952 x 5800 mm |

| Fabric Type | 100% Cotton Knit/Viscose/Polyester/Woven |

| Fabric Weight Range | 80-400g/m2 |

| Production Speed | 5m/min. (minimum)., 60m/min. (maximum) |

| Supply Voltage | 380VAC 50/60Hz |

| Control Voltage | 24VDC |

| Installed Power | 62kW *VARIES ACCORDING TO EQUIPMENT* |

| Rope Washing Part | 40kW |

| Rope Opener Machine | 22kW |

| Steam | 5.5-6 Bar pressure (Consumption: 0.7-0.9 steam kg/fabric kg) |

| Compressed Air | 6-8 Bar Pressure |

| Washing Water | 2-3 Bar Pressure |

| Water Consumption | 6-12 Lt for 1 kg fabric washing after dyeing |

*Variables such as quantity, fabric type, fabric fiber composition, types of dyeing/printing chemicals, their concentrations on the fabric, etc., may affect water consumption. Generally, the deviations from the provided values are minimal.